Product brief

AGV stands for Automated Guided Vehicle.

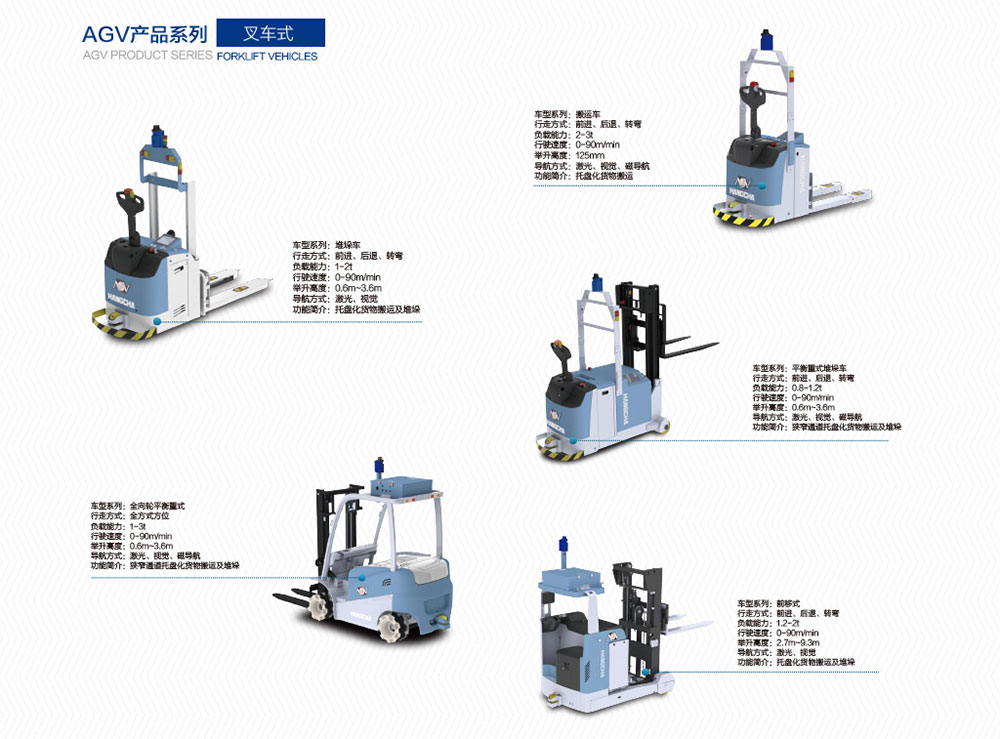

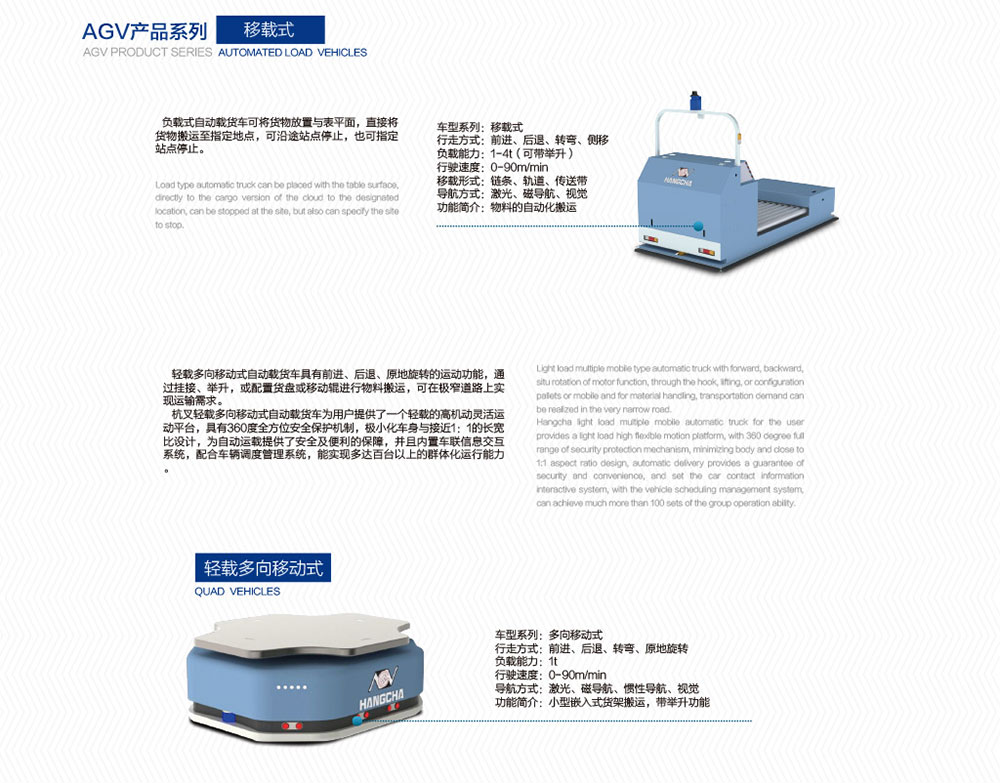

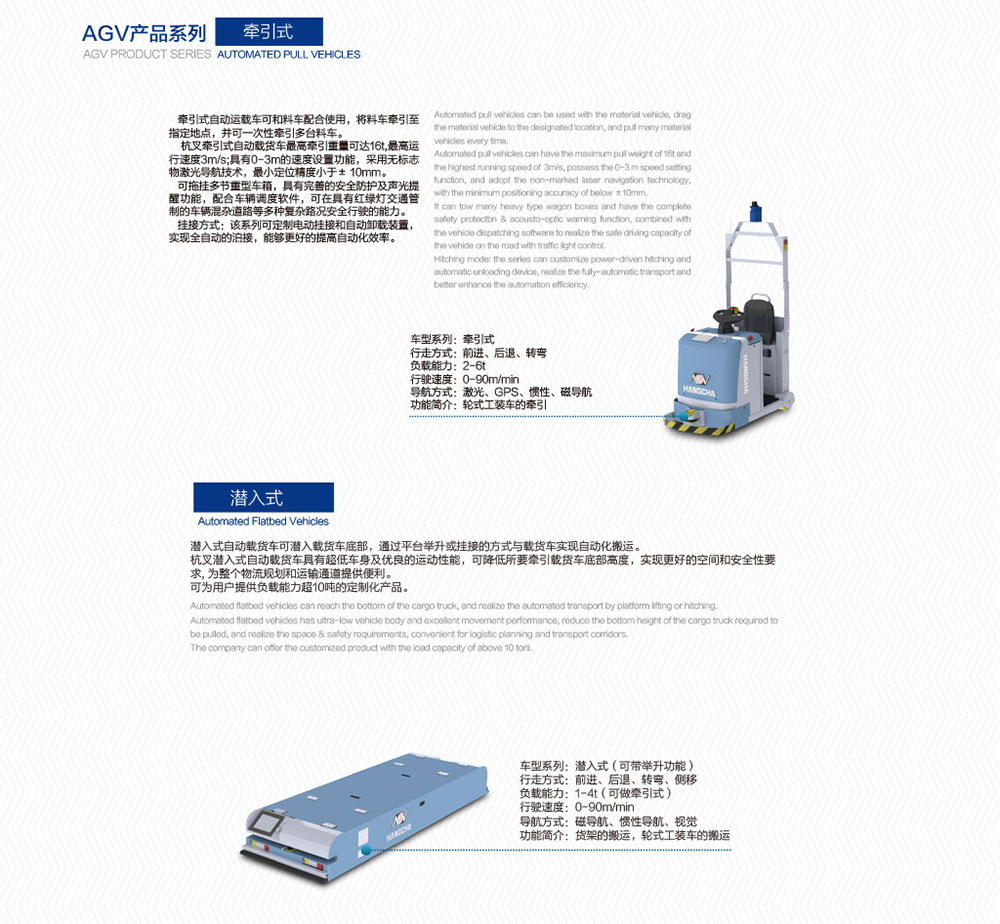

Transport robots refer to those equipped with automatic guidance devices such as electromagnetic or optical ones, capable of traveling along prescribed guidance paths, and featuring safety protection and various loading and unloading functions. As a leading domestic supplier of forklift products, Hangzhou Forklift Group's AGV product series cover forklift types, submersible types, transfer types, towing types and light-load multi-directional mobile types.

AGV stands for Automated Guided Vehicle.

An automatic steering device equipped with an electromagnetic or optical device, which can travel along the prescribed guidance path and has safety protection and multiple functions. As a leading domestic supplier of forklift products, our AGV product range covers forklifts, submersible forklifts, heavy-duty forklifts, traction forklifts and light-duty forklifts.

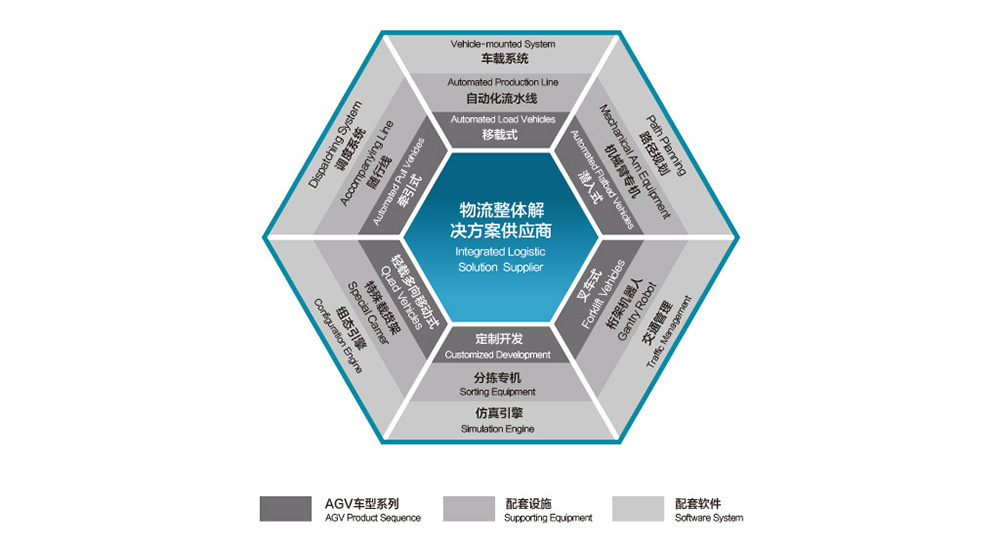

As a leading provider of overall logistics solutions in China, Hangzhou Forklift possesses professional logistics technology and rich project experience. In recent years, in response to the characteristics of low work efficiency and high labor costs in the logistics industry, a series of intelligent industrial forklifts have been custom-developed, including forklift type, submersible type, tow type and other AGVs. To achieve the era goals of Industry 4.0, Hangcha has designed and developed logistics dispatching management software, engineering application suites and optional suites. It has greatly improved and enriched the logistics product line, providing a strong guarantee for enterprises to enhance production efficiency and reduce production costs.

As a leading provider of overall logistics solutions in China, Hangzhou Forklift possesses the most professional logistics technology and rich project experience. In recent years, in response to the characteristics of low efficiency and high labor costs, a series of intelligent industrial forklifts have been developed, including forklift types, submersible types, and traction types, etc. Autonomous mobile car. To achieve the goal of Industry 4.0, logistics dispatching management software, engineering application suites and optional suites have been designed and developed. It has greatly improved and enriched the product line, providing a strong guarantee for enterprises to enhance production efficiency and reduce production costs.

Technology LEVDEL

The company has a strong technical force. We have mastered a series of technologies, including all-round motion mechanism and planning control for intelligent industrial transport vehicles, chassis motion mechanism and planning control, dynamic path planning and obstacle avoidance for AGVs, group collaborative planning and control, motor drive for AGV operation, AGV bus control system, construction of unknown environment maps, self-positioning and autonomous navigation for AGVs. And the rapid target recognition and positioning based on vision, listing the world's advanced technologies, forms the overall technical architecture of the company's intelligent industrial forklifts.

The annual output value rate of new products of Hangzhou Tea Group has reached over 30%. We have obtained 69 national patents for forklifts, participated in the formulation of 14 national and industry standards, and our new products with independent intellectual property rights have won over 50 national, provincial and municipal science and technology progress awards.

The company has strong technical strength. We have mastered a series of international advanced technologies required for intelligent mobile robots, including all-round motion mechanisms and planning control, bipedal motion mechanisms and planning control, dynamic path planning and obstacle avoidance for robots, multi-agent collaborative planning and control, robot joint motor drive, robot bus control system, unknown environment map construction, and robot autonomous positioning and navigation. And rapid target recognition and positioning based on robot vision.

The annual output value rate of Hangcha Group's new products will reach 30%. It has obtained 69 national patents for forklifts, participated in the formulation of 14 national and industry standards, and its new products with independent intellectual property rights have won more than 50 national and provincial and municipal science and technology progress awards.

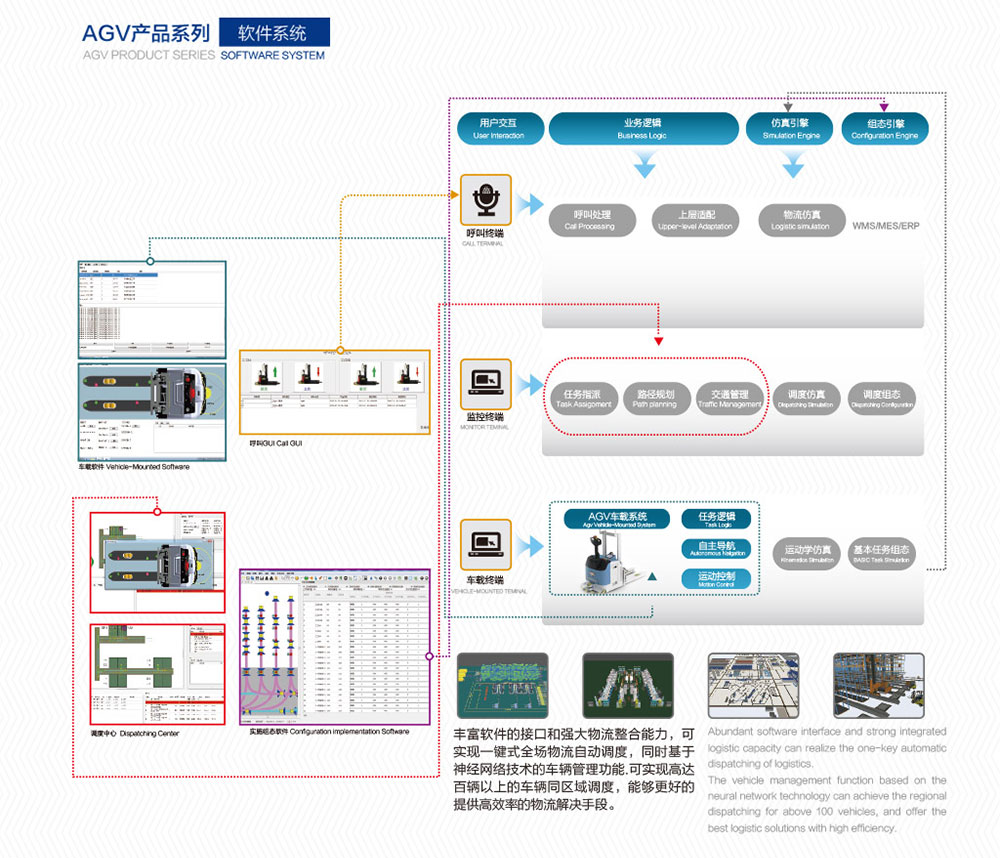

Software system

The Hangzhou tea automatic transportation vehicle software system includes vehicle management system software, simulation and configuration software, vehicle dispatching and traffic management software, covering system configuration, task management, intelligent dispatching, and logistics information interfaces. It provides users with information technology integration capabilities and can offer overall WMS/EMS solutions based on user requirements.

The Hangzhou tea automatic transportation vehicle software is a management software system based on a graphical interface. Users can understand the operation and transportation status of the vehicles and promptly issue abnormal alarms, greatly enhancing the convenience of vehicle group management. The system offers visual engineering configuration plans and schemes, capable of providing users with vehicle parameter configuration, task status configuration, route planning, action priority, task information planning and other contents.

The HANGCHA freight automation software system includes vehicle management system software, simulation configuration software, vehicle dispatching and traffic management software, covering system configuration, task management, intelligent dispatching and logistics information interfaces. It has comprehensive information integration capabilities and can provide WMS/EMS integrated solutions according to customer needs.

HANGCHA automatic freight vehicle software is a graphical and interface-based management software system that enables customers to understand the operational status and carrying conditions of vehicles, and promptly issue warnings for abnormal situations, facilitating vehicle group management. The system can provide visual project allocation plans and solutions, and comprehensively offer vehicle parameter configuration, task status configuration, path planning, operation priority, task information planning for customers, and other related information.